Automatic personnel protection for hazardous machinery

Conveyor Safety

The business challenge

Conveyor belts are commonly used in many industries. Although they enable quick and efficient transportation for a wide variety of materials, there are many hazards associated with working at or near a conveyor.

Health and Safety legislation requires employers to do everything practicable to prevent injuries, but even with the most comprehensive safety procedures in place, when people are working in hazardous environments and with hazardous machinery accidents can occur.

“Cyphertag® “hands-free” identification tags and readers provide life-saving services in waste management sites.”

Our RFID solution

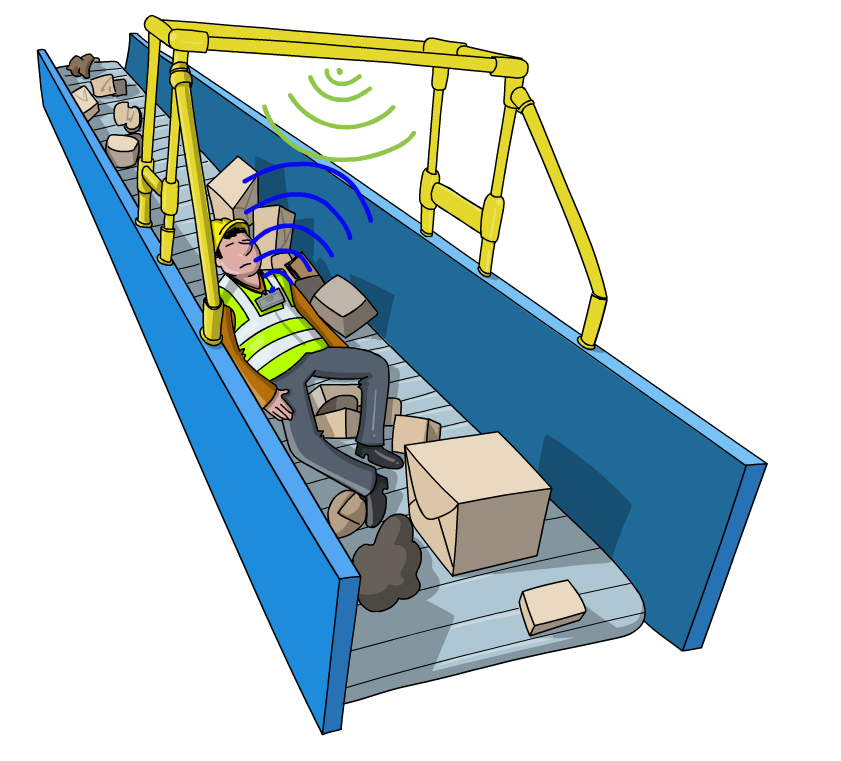

RFID offers a simple solution to prevent accidents and protect your people. An RFID detection and alert system sense the presence of people within a safety zone on and around a conveyor belt.

This means if a person wearing an active RFID tag enters the defined hazardous zone an alarm will sound, and an emergency stop will be automatically activated.

This will happen even if the person is unconscious, incapacitated or buried beneath material, potentially averting a serious accident. Once a person is clear of machinery the conveyor belt can restart quickly and safely.

Safetech, a specialist conveyor system supplier, uses our Cyphertag® product globally, in their latest product Guardian Ultra, to avoid accidental injury to staff falling on the belts, creating safer, secure areas of work for many employees in waste management around the world.

How does it work?

Our RFID solution is effective as it benefits from the full performance monitoring capability, robust performance, and longevity of our Cyphertag® product. Our state-of-the-art technology which meets global safety requirements - validated by an independent test house offers:

- Digital technology achieves high resilience against background noise.

- Self-monitoring assures reliability and performance.

- Real-time data and diagnostics give immediate feedback to the operator.

- A lighter, stronger structure can be configured to bridge any size of equipment.

- Versatile design allows the material to pass without obstruction.

The Impact

Our touch-free RFID tag technology will prevent injury, meaning people will be safer. And by recognising potential hazards ahead of them occurring the conveyor system will be kept up and running, adding speed, accuracy, and efficiency as well as prioritising safety and security to your business operations.

.jpg)